Moving commercial kitchen equipment can be a complex task, but with careful planning and proper equipment, it can be done efficiently and safely. We will discuss the steps involved in moving commercial kitchen equipment, along with some helpful tips to ensure a smooth transition.

Whether you’re relocating your restaurant or upgrading your kitchen, knowing how to move your equipment correctly is crucial to avoiding damage and maintaining operations. From assessing your equipment and creating a moving plan to disassembling, packing, and transporting, we will cover everything you need to know for a successful move.

So let’s dive in and learn how to move commercial kitchen equipment like a pro.

The Importance Of Proper Planning

Moving commercial kitchen equipment can be a daunting task, but with proper planning, you can ensure a smooth and efficient process. Taking the time to plan your move carefully will not only help you avoid potential mishaps and delays, but it will also safeguard your valuable equipment. In this section, we’ll discuss the key components of proper planning when it comes to moving your commercial kitchen equipment.

Creating A Detailed Checklist

One of the first steps in planning your commercial kitchen equipment move is creating a detailed checklist. This checklist will serve as your roadmap, keeping you organized and ensuring that no essential tasks are overlooked. Here are some important points to include in your checklist:

- Document all the kitchen equipment that needs to be moved

- Take inventory of any spare parts, accessories, or manuals that need to accompany each piece of equipment

- Contact professional movers or equipment relocation services to get quotes and compare prices

- Secure any necessary permits or permissions for moving large or specialized equipment

- Ensure that all equipment is properly cleaned, disconnected, and ready for transportation

Determining Equipment Placement

Determining the placement of your equipment in the new location is another critical aspect of proper planning. Here are some key considerations to keep in mind:

- Measure the dimensions of the new space to ensure that your equipment will fit

- Create a floor plan or layout that maximizes workflow efficiency

- Keep in mind the spacing requirements between equipment for safety and ventilation

- Consider the proximity of electrical and plumbing connections

Safety Precautions And Guidelines

The safety of moving commercial kitchen equipment should be a top priority to avoid any accidents or damage during transportation. Following proper safety precautions and guidelines is crucial to ensure a smooth and secure move. In this blog post, we will discuss two important aspects of ensuring safety: securing equipment for transport and ensuring proper handling. Let’s dive in!

Securing Equipment For Transport

Securing the commercial kitchen equipment properly is essential to prevent any damages or accidents during transportation. Here are some safety precautions and guidelines to follow:

- Before moving, make sure to disconnect all power sources and secure any loose cords. Use zip ties or twist ties to bundle and secure cords together to avoid any tripping hazards.

- Empty and clean all equipment thoroughly. Remove all perishable items, clean all surfaces and components, and ensure that there are no food residues or spills left behind.

- Take proper measurements of the equipment and the delivery vehicle to ensure a proper fit. Use straps or heavy-duty ropes to secure the equipment securely in place.

- Consider using moving blankets or padding to protect the equipment from scratches or dents during transportation. Wrap the equipment carefully, ensuring that no sharp edges are exposed.

- If necessary, disassemble the equipment into smaller parts for easier transportation. Label and secure all loose parts to avoid misplacing or losing them.

- Do not overload the delivery vehicle. Distribute the weight evenly and avoid stacking heavy items on top of delicate equipment.

Ensuring Proper Handling

Proper handling of commercial kitchen equipment is important to prevent any injuries and damages. Here are some safety precautions and guidelines to follow:

- Ensure that all individuals involved in the moving process are trained properly to handle the equipment. Provide them with clear instructions and safety guidelines.

- Use proper lifting techniques when moving heavy equipment. Bend your knees, keep your back straight, and lift with your legs to avoid any strains or injuries.

- Take extra precautions when moving equipment with sharp or protruding parts. Use gloves and handle with care to prevent any cuts or injuries.

- Communicate effectively between team members during the moving process. Use hand signals or walkie-talkies to coordinate movements and avoid accidents.

- Avoid dragging or sliding equipment on the floor, as it can cause damage to both the equipment and the floor. Instead, use dollies or carts designed for moving heavy items.

- If required, use additional safety measures such as ramps or stair climbers to navigate through difficult terrains or obstacles.

By following these safety precautions and guidelines, you can ensure a safe and hassle-free move for your commercial kitchen equipment. Remember, proper planning and attention to detail are key to a successful move!

Expert Strategies For Disassembly And Packing

When it comes to moving commercial kitchen equipment, expert strategies for disassembly and packing are essential to ensure a smooth and efficient process. Proper disassembly and packing techniques can help protect the equipment from damage during transit, ensuring that it arrives at its destination in optimal condition. In this blog post, we’ll explore some expert strategies for disassembling and packing commercial kitchen equipment, focusing on labeling components and hardware and protecting fragile equipment.

Labeling Components And Hardware

Labeling components and hardware is a crucial step in the disassembly process. Clearly labeling each component and its corresponding hardware can streamline the reassembly process at the new location. Use bold, easy-to-read labels to indicate which parts belong together, and consider creating an inventory list to keep track of all the components.

Protecting Fragile Equipment

When it comes to fragile equipment, proper protection is paramount to prevent damage during the move. Consider using durable packaging materials such as bubble wrap, foam padding, and packing peanuts to protect delicate components. Additionally, securing loose parts and components with zip ties or tape can help prevent shifting and potential damage during transit.

Choosing The Right Transportation Method

Transporting commercial kitchen equipment requires careful consideration of the best transportation method. Selecting the right mode of transport is crucial to ensure the safe and efficient transfer of heavy and delicate equipment. Whether it’s using specialized trucks, professional movers, or freight services, choosing the appropriate transportation method is essential to safeguard the equipment during the move.

Moving commercial kitchen equipment requires careful planning and consideration. One of the crucial decisions you’ll need to make is choosing the right transportation method. This will ensure that your equipment arrives safely and in good condition at its new location. Here are two key factors to consider when deciding on the best approach:

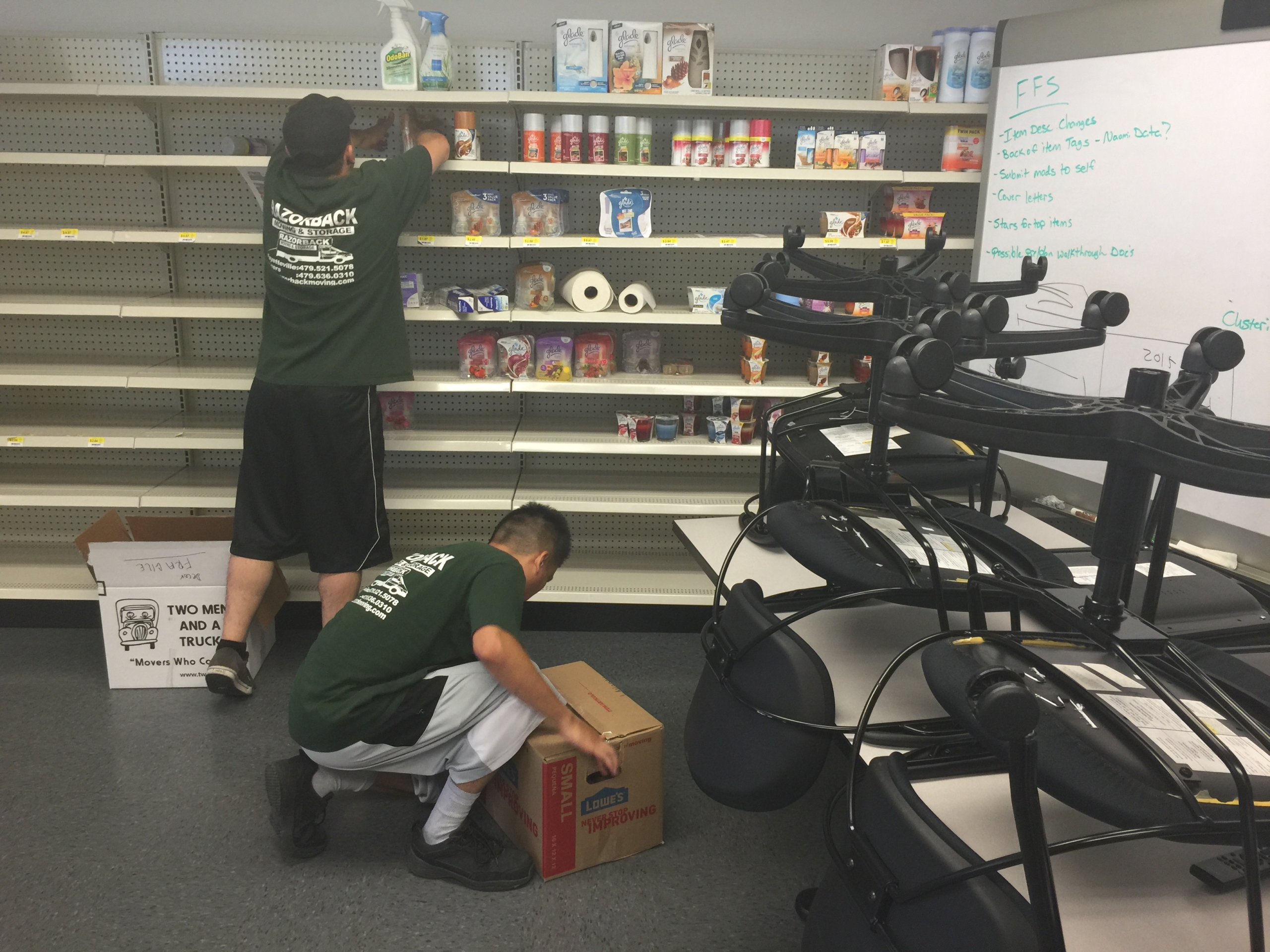

Utilizing Professional Moving Services

When transporting commercial kitchen equipment, utilizing professional moving services can offer numerous benefits. They have the expertise and experience to handle various types of equipment, from heavy appliances to delicate machinery. Professional movers use specialized tools and equipment to ensure safe transportation, minimizing the risk of damage during transit. They also provide insurance coverage, giving you peace of mind knowing that your valuable equipment is protected. Additionally, hiring professionals saves you time and effort, allowing you to focus on other aspects of your move.

Selecting Appropriate Packaging Materials

Proper packaging is another crucial aspect when moving commercial kitchen equipment. Selecting appropriate packaging materials will provide the necessary protection against bumps, vibrations, and other potential hazards during transit. Here are some essential packaging materials to consider:

- Packing tape: Securely seals boxes and prevents them from opening during transport.

- Bubble wrap: Excellent for wrapping fragile equipment, providing cushioning and protection against impact.

- Foam padding: Ideal for filling empty spaces and gaps in packaging, providing additional cushioning and stability.

- Plastic wrap: Helps keep appliance doors and drawers closed, preventing any unwanted movement during transport.

- Corrugated cardboard sheets: They can be used to reinforce boxes or provide an extra layer of protection for larger equipment.

- Corner protectors: Shield vulnerable corners and edges of equipment from scratches and damage.

By carefully selecting the right packaging materials and employing proper packing techniques, you can ensure that your commercial kitchen equipment remains intact and safe throughout the move.

Efficient Reinstallation And Setup

Efficiently reinstalling and setting up commercial kitchen equipment is crucial for a smooth transition and uninterrupted operations. Following the manufacturer’s guidelines, testing and calibration are essential steps in ensuring a successful installation. Let’s delve into each of these aspects in detail.

Following the Manufacturer’s Guidelines

When it comes to reinstalling and setting up your commercial kitchen equipment, it is essential to meticulously follow the manufacturer’s guidelines. Manufacturers provide specific instructions to ensure the correct installation and optimal performance of their equipment. By adhering to these guidelines, you can minimize the risk of damage, safety hazards, and unnecessary breakdowns.

Installing kitchen equipment without following the manufacturer’s guidelines can result in inadequate functionality, inefficient energy consumption, and premature wear and tear. Moreover, it may void the warranty, leaving you responsible for any repairs or replacement costs.

Testing And Calibration

After reinstalling your commercial kitchen equipment, thorough testing and calibration are vital to ensure its proper functioning. This step allows you to identify any issues and make necessary adjustments, guaranteeing optimal performance and longevity.

Testing involves evaluating each component of the equipment and verifying its functionality. This includes checking electrical connections, gas lines, plumbing, and controls. Any loose connections or faulty parts should be addressed immediately to prevent future problems.

Calibration is equally crucial for certain equipment, such as ovens, refrigeration units, and temperature sensors. It involves setting the equipment to operate at its intended performance level, ensuring accurate temperature control, energy efficiency, and product quality.

By conducting thorough testing and calibration, you can minimize the risk of breakdowns during operation and enhance the overall productivity and reliability of your commercial kitchen equipment.

In conclusion, efficient reinstallation and setup of commercial kitchen equipment are essential for a successful transition and seamless operations. By diligently following the manufacturer’s guidelines and conducting thorough testing and calibration, you can ensure optimal performance, longevity, and safety. Remember, investing time and effort in the setup stage will pay dividends in the long run.

FAQs On Moving Commercial Kitchen Equipment

Faq 1: How Do You Prepare Commercial Kitchen Equipment For Moving?

To prepare commercial kitchen equipment for moving, start by cleaning and sanitizing the equipment thoroughly. Disconnect all utilities and secure any loose parts. Remove any detachable items, such as shelves or trays, and pack them separately. Use proper packing materials and secure the equipment to prevent any damage during transit.

Faq 2: Can Regular Moving Companies Transport Commercial Kitchen Equipment?

Yes, regular moving companies can transport commercial kitchen equipment. However, it is essential to ensure that the moving company has experience in handling such equipment. Verify that the company has the necessary equipment, expertise, and insurance to handle the transportation of your valuable commercial kitchen equipment safely and securely.

Faq 3: What Is The Best Way To Protect Commercial Kitchen Equipment During A Move?

The best way to protect commercial kitchen equipment during a move is by using appropriate packing materials, such as bubble wrap, cushioning foam, and moving blankets. Secure the equipment in a sturdy crate or box and use straps or ropes to keep it in place.

Label the packaging clearly and transport it with care to minimize the risk of damage.

Faq 4: Should I Disassemble Commercial Kitchen Equipment Before Moving It?

In most cases, it is recommended to disassemble commercial kitchen equipment before moving it. Disassembling the equipment makes it easier to transport, reduces the risk of damage, and aids in efficient packing. However, consult the manufacturer’s instructions or seek professional advice to determine if specific equipment requires disassembly before moving.

Conclusion

Moving commercial kitchen equipment requires careful planning and coordination. The process involves assessing the equipment, ensuring proper packaging, and securing reliable transportation. By following the guidelines outlined in this blog post, businesses can minimize the risks associated with equipment transportation and ensure a smooth and efficient relocation.

With attention to detail and effective implementation of best practices, the process can be streamlined for maximum success.

Hello, decor aficionados! I’m Sufian Fahim, the creative mind and blog writer behind the scenes at Girlsbar-BerryHome. With a passion for home decor, I weave stories and insights to inspire your journey in transforming spaces into personalized sanctuaries. Having immersed myself in the design world, I curate content that reflects the latest trends, timeless classics, and innovative ideas to make your home uniquely yours. Join me on a delightful exploration of colors, textures, and styles as we navigate the exciting realm of home decor together. Get ready for a blend of practical tips, imaginative inspirations, and a touch of my flair. Let’s make every corner of your home a story waiting to be told! Welcome to Girlsbar-BerryHome – where style meets storytelling, and your home becomes a canvas for self-expression.